The manufacturing process the manufacture of asphalt roofing products is a continuous process performed on a roofing machine that begins at one end with a roll of core material and concludes at the other end with the finished product.

Roofing felt manufacturing process.

The batts of felted material must be hardened or matted together in order to create thick densely felted material.

Thinner lighter shingles with a higher resistance to fire are made on a base of fiberglass.

In a typical process the fiberglass membrane is made by chopping fine glass filaments and mixing them with water to form a pulp which is formed into a sheet.

Organic felt mats are made of cellulose fibers obtained from recycled waste paper or wood.

During the next step heated drying in drums and the wet looper provide the heat and time respectively for the asphalt to penetrate the felt.

Why use roofing felt paper.

Roofing shingles and materials plus factory certified roofers including ratings from real homeowners from north america s largest roofing manufacturer.

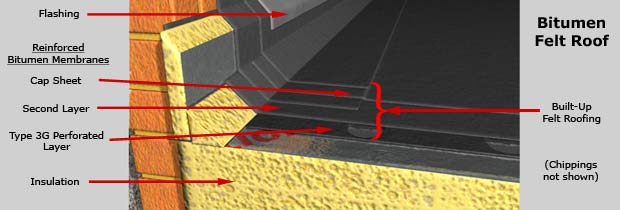

Rolls of base felt are pulled on rollers through large tanks of bitumen mixes until they are saturated with the tar like bitumen mixture producing rolls of water resistant but breathable material.

Putting a new roof over your home is a big improvement and one that comes with plenty of questions.

Below are a few parts of the re roofing process to help ease your mind and answer questions.

These fibers are reduced to a water based pulp formed into sheets dried cut into strips and wound onto rolls.

Our management team has positioned gap roofing to remain a leader in the industry by championing a lean but high quality production process for our raw materials and final products.

Roofing felt is comprised of a base made from natural materials such as wood cellulose or synthetic ones such as fiberglass or polyester and then coated or saturated with a protective coating such as bitumen asphalt which repels water but still allows the product to breathe.

The first step in this process is subjecting the batts to heat and moisture.

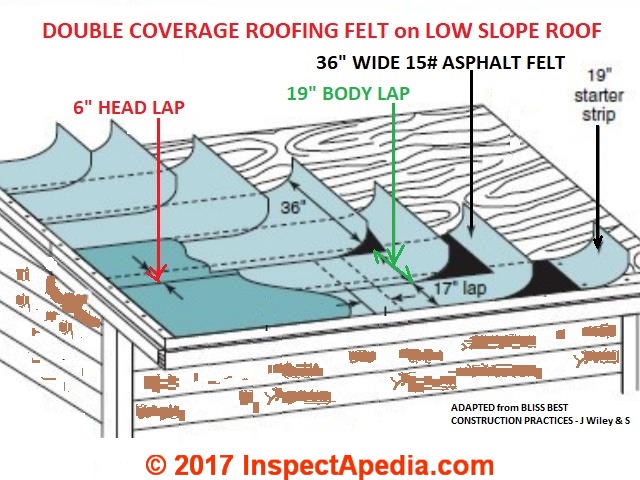

Manufacturing process roofing felt is manufactured in roll format.

Roofing felt is manufactured in roll format.

In the saturator dip section the saturated felt is drawn over a series of rollers with the bottom rollers submerged in hot asphalt at 205 to 250 c 400 to 480 f.

Our job throughout the entire roofing process is to keep an open communication line with you.

In order to do so the batts are passed through a steam table.

Residential and commercial roofing shingles slate roof ventilation roof underlayments asphaltic and tpo roof membranes.

Our competitive advantage is our manufacturing process.